Digital Transformation has gained momentum in the recent years and it is expected that there will be more than a two-fold increase in the deployment of digital services over the next five years. Aircraft manufacturers seek to improve operations and adapt new ways of working with an increased focus on digitization, sustainability and creation of green aircraft.

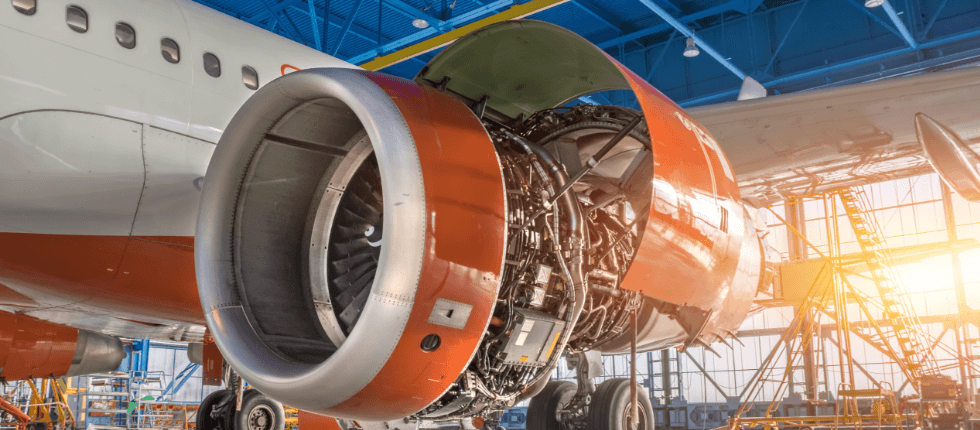

The need to build agile, resilient, predictive and adaptive supply chains has prompted OEM's to drive rapid change with DevOps, encourage innovation through the ecosystem and create new business models using IoT along with a continued focus on aftermarket services and MRO.

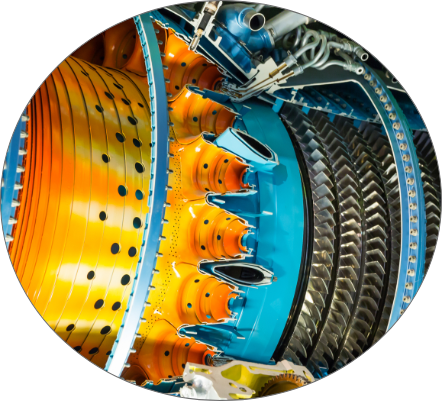

QuEST's deep domain expertise in the A&D sector combined with our capability to deliver sustainable solutions enables customers to solve the challenges of the future without losing sight of the current needs. We drive business outcomes for customers through the convergence of mechanical, digital and software engineering services. Our multidisciplinary engineering expertise helps to provide services across the complete product life cycle.

For over two decades QuEST Global has worked with the foremost A&D leaders to become a Trusted Thinking Partner in aviation. Our in-depth understanding of the A&D industrial landscape, digital innovations and enhanced services capabilities, makes us a preferred partner of choice to drive transformational business change.