Develop solutions that matter

Accelerated Product Development

Full product ownership of equipment software

Yield Improvement

Achieve extraordinary outcomes with digital transformation

Predictive maintenance of expensive equipment to increase uptime

AI based visual inspection for reducing wastage & improving yield

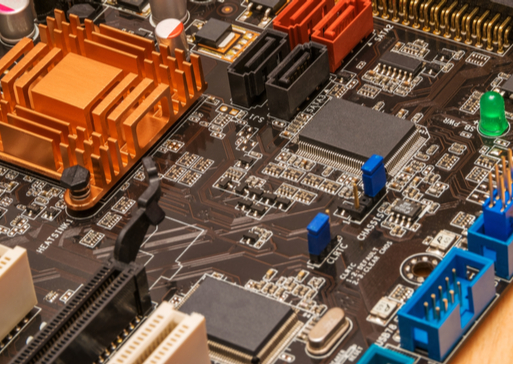

Your 3M partner - Manage, monitor & maintain SEMI equipment

With award-winning solution accelerators right from Tool Control to Factory Automation